Brief description

The technology we used is from Germany. We can provide you top level machines with competitive price and perfect services. We are integrated with design, R&D, production, marketing, and after-sales services.

Tez tafsilotlar

Kelib chiqishi: Xitoy (Xalq Respublikasi)

Tovar nomi: EMM

Model Number: DM-402

Xizmatdan keyingi xizmat ko'rsatish: Xorijiy texnika xizmatini ko'rsatish uchun muhandislar mavjud

Type: FIPFG formed in place foam gasket manufacturing

Strip width: Micro type: 2-8mm; Standard type: 5-30mm

Technology: Mixing head designed and manufactured in Germany

Dosing system: Barmag metering pump

Control system: Taiwan Syntec CNC system with hand controller

Driving system: Panasonic servo motor

Cleaning system: Water rinsing, built-in the mixing head.

Working speed: 0-12m/s, usually be 6-10m/s

Raw material: Polyurethane, PU, Silicon, other liquid material

Certifications: CE, ISO, RoHS, SGS, CQC, etc.

Mahsulot tavsifi

2 components EMM automatic PU foam sealing gasket making manufacturing machine

Ushbu mashina ikkita xom ashyo bilan birlashtirishi va oldindan o'rnatilgan pozitsiyasiga, yivga, qolipga yoki ishlov beriladigan tekis yuzasiga va boshqalarga tekkizishi mumkin. Kimyoviy reaksiya natijasida suyuq xom ashyolarni elastik sızdırmazlık ipi sekundlarda hosil qiladi. Qo'shish yoki kesish nuqtasi yo'q, shuning uchun uning ta'sirini boshqa turdagi siqish bilan taqqoslash ancha yaxshiroq va hayotdan uzoqroq foydalanadi. Va shakllantirish jarayonida sızdırmazlık ipi yuzasi juda yumshoq va hech qanday çatlaksız bo'lib, uning muhr ta'siri mukammaldir. Va, tabiiy ravishda va mahkam ishlov beradigan narsaga yopishib olishi uchun, hech qanday yopishtiruvchi ishchi kerak emas, katta xarajat mehnat va vaqtdan qutqariladi va hokazo.

Ko'pikni yopishtirish uskunalari shamollarni, yorug'likni, avtotransportni, ishlov berish sanoatini va hokazolarni nazorat qilish kabi ko'plab sohalarda ishlatiladi. Sızdırmaz, yog 'o'tkazmaydigan, suvga bardoshli, sönümleme, shovqin bardoshli va muhrlab, va hokazo. ul / CE, MIL-STD-167, EN50298 kabi sertifikatlar bilan ta'minlangan.

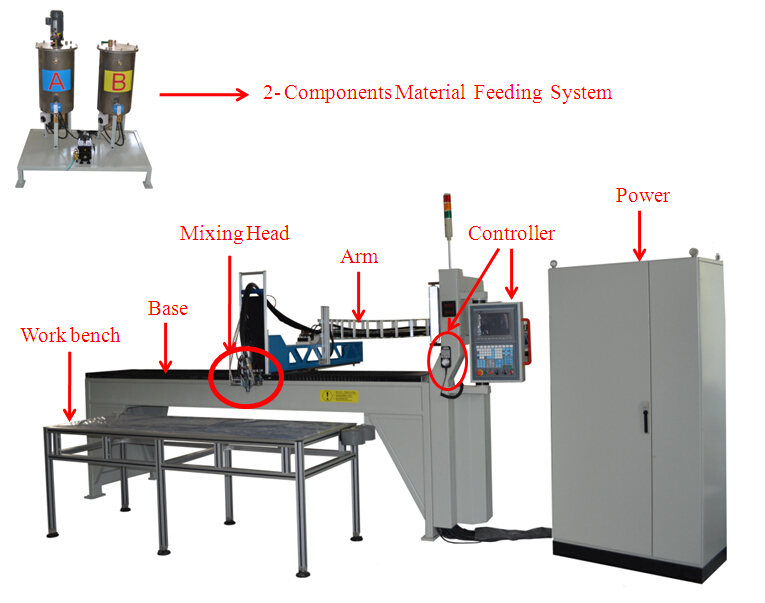

Gasket making machine Construction:

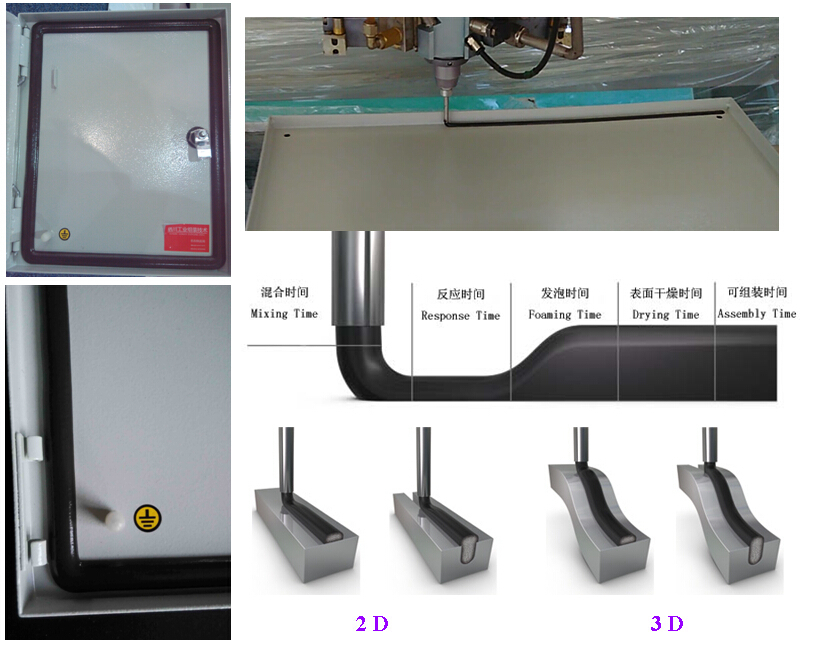

Gasket making machine Raw Material Reaction Principle:

Gasket making machine Main Parts

1. Mixlash boshi:

Suvni yuvish va modulli dizayn

2- / 3- komponentli aralashtirish boshini yuqori bosimli suv bilan yuvish tizimi va dinamik aralashtirish tizimi bilan, suyuqlik bilan yopishtirish, yopishtirish va suv bilan yopishtirish uchun yuqori viskozli polimer reaktsiya materiallariga ishlatish uchun.

2. Operatsion tizimi:

SYNTEC dan 180 daraja CNC tizimi, ko'p tilni tanlash, juda ko'p ishlatiladigan ma'lumotni saqlash, Plus USB interfeysi va G-kodli dasturni saqlash.

3. Xom ashyolar:

Ikki marta devorli zanglamaydigan po'latdan, avtomatik ravishda nazorat qilish harorati.

4. Ish stoli:

Alyuminiy qotishmasi kuchli va bardoshli.

5. Dozalash tizimi:

Barmag o'lchov nasosi, Panasonic servo vosita, mikroskale yopishtirish ishlaydi.

6. Boshqaruvchi:

SYNTEC oson, tezkor va qat'iy javob berdi.

7. Haydash tizimi:

Kompaniya servo vosita, barqaror, uzoq muddat foydalanish, o'nlab soat davomida ishlashi mumkin.

Our Gasket making Machine Equipment Advantage:

| Our Company, Jinjie | Some other companies | |

| Texnologiya | From German, top level, mature and stable | R&D in China, Chinese level, in developing |

| Karıştırıcı bosh | Made in Germany (Germany manufacturing and processing technology, and quality) | Made in China, Chinese quality. |

| Ish tartibi | 2D or 3D for choice (could process special 3D patterns) | 2D only |

| Boshqarish tartibi | 8 axis linkage as a whole (1X+1Y+1Z+2Mixing+2Reserved, Could adjust & change to 3-components equipment or adding auto material feeding system according to needed.) | 3 axis + other control systems, need matching |

| Yelimlash kengligi (Standard type) | 5-30 mm | 8-30mm |

| Yelimlash kengligi (Micro- type) | 2-8 mm | 3-8mm |

| Qayta joylashishni aniqlash to'g'riligi | +/-0.03mm | +/-0.05mm |

| Dozalash | 0.5~5g/s | 1~4g/s |

| Continous working time | can keep working for a whole day (there is a special coating on the mixing head to prevent residual) | Frequently temporarily stop for cleaning residual |

| Processing capability of factory | machine shop belongs to ourselves, Jinjie | Processed by another company, then assembled in another place. |

| Offer | Very competitive | Higher |

Gasket making machine Standard type equipment specifications:

| Texnik xususiyatlari | Ba'zi boshqa ma'lumotlar | |||

| Mechanical Arm | 6*3 m | Texnologiya | Germaniyadan | |

| Workbench | 2.4*0.9 m | Karıştırıcı bosh | Germaniyadan | |

| Moddiy dastgoh | 1.2*0.85 m | Operatsiya | Tayvanning Syntec, CNC tizimidan | |

| Ish strokasi | 2.4*1.2*0.25 m | Al tekshirgichi | Tayvan Syntec dan | |

| Yelimlash kengligi | 5-30 mm | Motor | Kompaniya Servo Dvigatel | |

| Gluing Precision | 0.01 mm | O'lchov pompasi | Germaniyadan Barmag | |

| Ishlash tezligi | 0-12 m / min | Tozalash | Suv o'stirish | |

| Maksimal tezlik | 30 m/min | Materiallar namlagichlari | Ikki marta devorli zanglamaydigan po'latdan, avtomatik ravishda nazorat qilish harorati | |

| Qayta joylashishni aniqlash to'g'riligi | +/- 0.03 mm | Boshqarish tartibi | 8 eksa aloqasi, 1X+1Y+1Z+1mixing+2metering+2reserving | |

| Dozalash | 0.5-5 g/s | Ish tartibi | 2D yoki 3D | |

| Filling Accuracy | 0.1 g/s | Asosiy rang | Kumush kulrang, rasmga qarang, yoki qora, qizil va hokazo. muhokama qilinmoqda. | |

| Aralashtirish tezligi | 0-3000 rad/min | Maxsus tayyorlangan, OEM, ODM | Yaxshi Muammo yo `q. | |

| Aralash nisbati | 1:10~10:1 Adjustable | Sertifikatlar | Idoralar, RoHS, ISO va boshqalar. | |